Lithium battery has been widely used in life and in industrial productions. Since 2007 when Apple issued its smart phones and then the tablet computers, we have come to a world of intelligent time, the popularization of portable devices such as smart phones and tablet computers, promote the great sales of lithium batteries. For lithium battery which is used in mobile communications, whether it can pass the rigorous tests and to be found as reliable, whether it can be used safely and has a long life, for all the above questions, are not only the challenges faced by the Lithium battery R&D engineers but also are very important elements that engineers need to consider when selecting a appropriate battery. Itech IT6412 brings the latest lithium battery safety test solutions. It can safely and efficiently help to test portable and wearable devices’ lithium batteries in all aspects such as tests of recycled charge-discharge, protection functions, battery protection boards and etc.

Charge-discharge recycling test

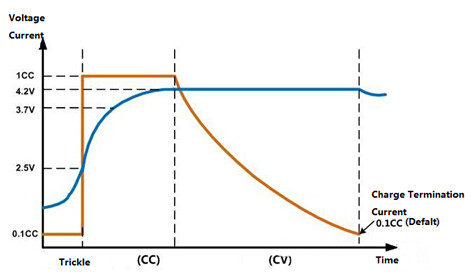

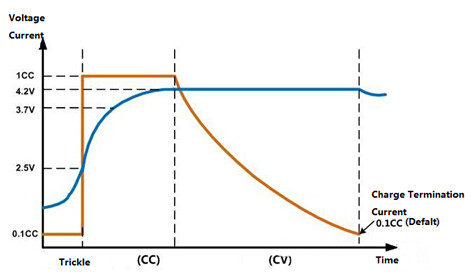

Lithium battery charging can be divided into two stages: CC charging, it will turn to CV when It is close to end. Charge by 800mA (charge rate 1C) by CC, the battery’s voltage will rise in a big slope at the beginning stage; when voltage is near 4.2V, it will become 4.2V CV charging, the current gradually descends, there’s no big voltage variation. When charging current reduces to 1/10C (around 80mA), it will be regarded as close to full, you may stop charging. Lithium battery has demanding charging requirements, and need to ensure that the voltage stop accuracy is within 1%. Lithium battery discharging tests requires us to test under different temperatures, observe battery change, record battery capacity.

Figure1: lithium battery charging waveform

ITECH IT6412 dual-channel high-speed high-precision liner DC power supply is specially designed for batteries (for portable battery-operated products), the current can be either positive or negative, have a unique battery charge-discharge mode, monitor battery, current and charged capacity. Besides, IT6412 has oscilloscope functions, test engineers can press screenshots on the front panel to save waveform graphics in the inserted USB storage disk for further analysis very conveniently.

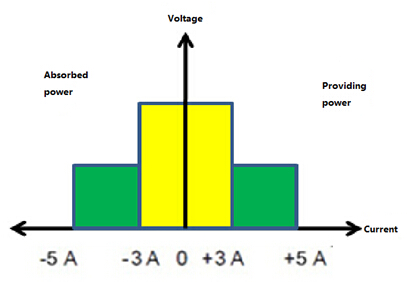

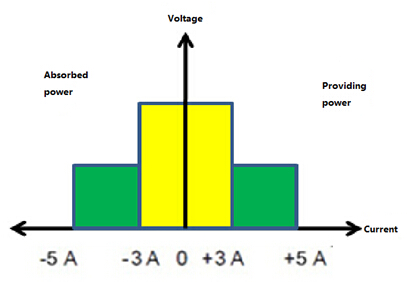

Figure 2: IT6412 output voltage, current

A single IT6412 dual-channel bipolar power source can simultaneously output current and absorb current, which makes test engineer’s work more efficient and helps to monitor lithium battery working situations in a fast way.

Lithium battery safety function test

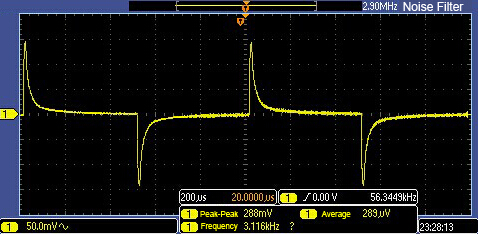

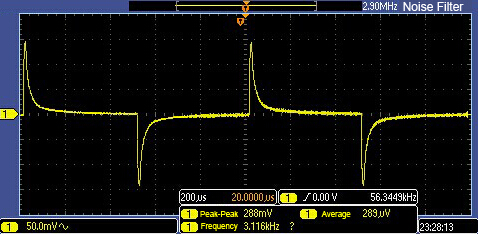

The lithium safety tests includes: over-charge protection, over-discharge protection, and short-circuit protection. According to International GB/T18287-2000 test standards, need to test battery’s protection current’s variations and response time when it’s overshoot, over-discharge and short-circuit. because the protection instant and short-circuit response time is very short, normally in hundreds of us level, thus it has very rigid requirements on testing power source’s response time. It6412 is a high-precision liner power source with ultra-fast transient response time, less than 50us response time to recover back to 50mV when 50-100% load. So IT6412 can fully be qualified to do lithium batteries’ ms level tests.

Figure 3: IT6412 transient response time waveform

Lithium battery protection board test

With the rapid development of portable intelligent products, lithium batteries need board protection under highly frequent charge-discharge processes. Protection board is a charge-discharge protection of serial lithium batteries, it can extend battery use life. So battery protection circuit test is one of the important safety test items. As a lithium protection board test equipment, its precisions must be very ultra-high, such as when doing over-charge voltage protection test, need to simulate the cell’s voltage precision up to several mV. Protection board’s idle current is only several uA. Transient response time is an important index of battery protection board tests as well.

Figure 4: Lithium battery protection board test diagrammatic sketch

Itech IT6412 DC power source’s ultra-fast response time can quickly test protection action time . It can do quick A/D sample and current resolution up to 100nA, able to test uA level idle current. What’s more, IT6412 has output internal resistance adjustment function, it can exactly simulate a battery charge-discharge conditions that test engineers will encounter in actual use, so as to obtain more accurate measurement.

Figure 5: Itech new arrival—IT6412 dual-channel bipolar DC power source

With the rapid development of portable electrical devices, lithium battery will play a more and more important role in our daily life due to its recycled excellent performance, high charging efficiency, and pollution-free features. Therefore battery testing requirements will surely be more demanding, Itech as the outstanding T&M instrument manufacturer, will constantly devote to the technology innovation and make as much contribution as we can to lithium batteries’ using safety.

PV/Energy Storage

PV/Energy Storage

Electric Vehicle

Electric Vehicle

Battery

Battery

Battery recycling

Battery recycling

Semiconductor / IC

Semiconductor / IC

Power Supply

Power Supply

Industrial Electronics

Industrial Electronics

Research/Education/Others

Research/Education/Others

Medical Electronics

Medical Electronics

Automotive Electronics

Automotive Electronics

IoT

IoT